Fittings production / Uozumi Fittings

3D modeling, digital manufacturing / TERADA 3D WORKS

Light guide plate design / Shizuoka Giken Kogyo Co.

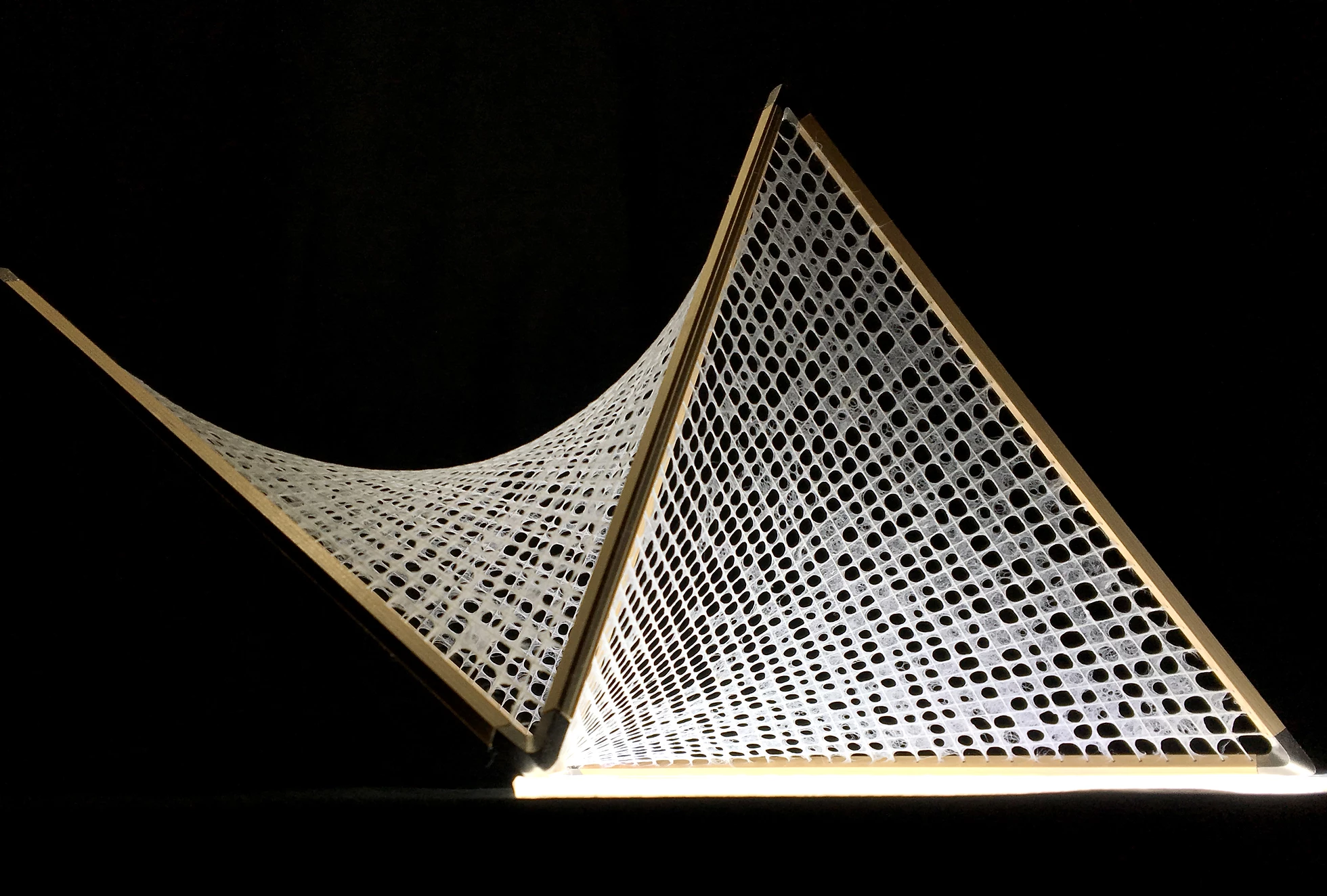

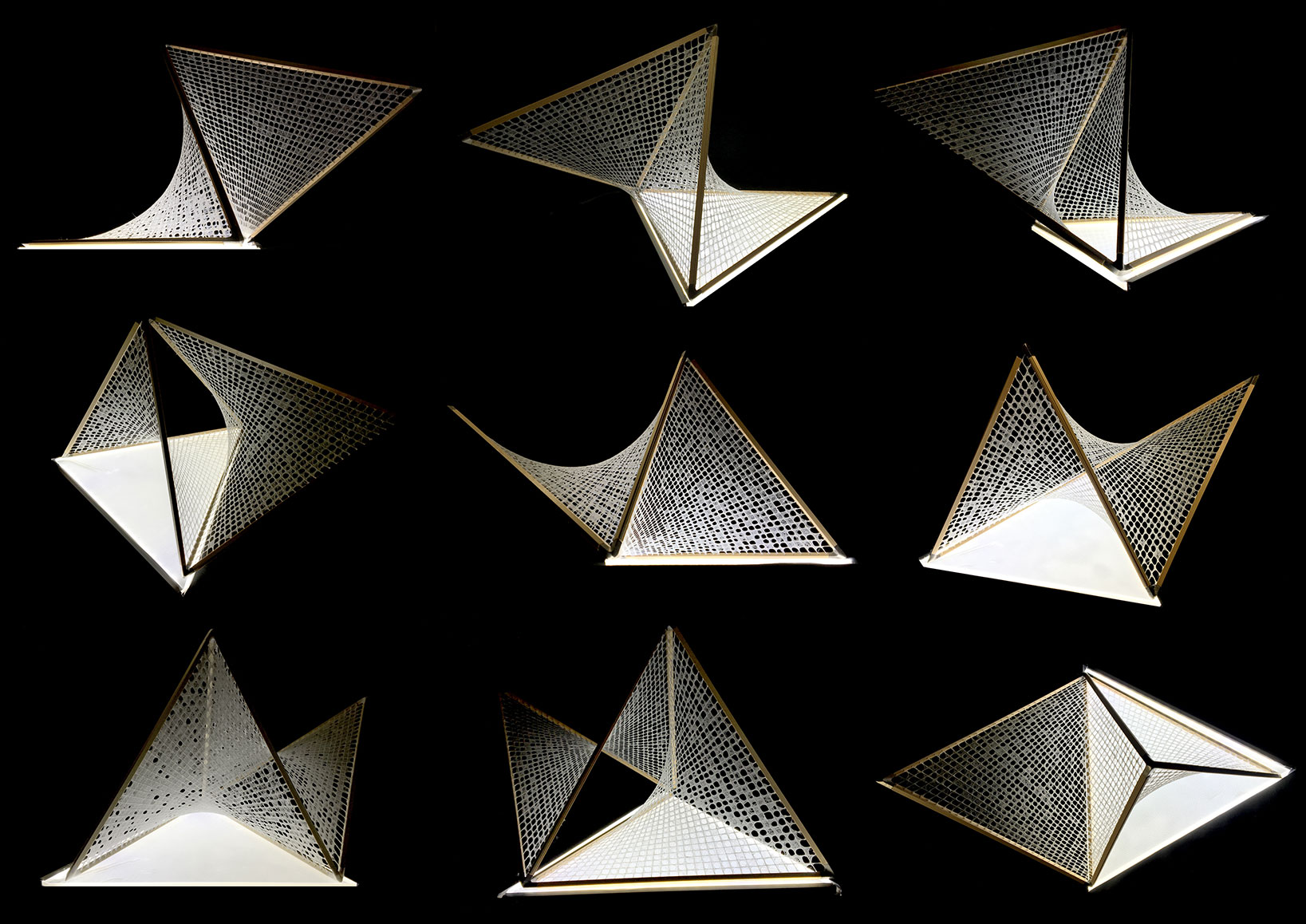

Washi paper lighting produced for the Lexus Takumi project.

The HP shell structure of straight lines was designed using 3D technology, and a three-dimensional frame made of cypress wood was produced using titanium joint parts output from a 3D printer.

The lines are transformed into surfaces by repeated drying.

The cypress wood was processed by a carpenter.

Using a custom-made triangular light guide plate as a base and changing the way it is placed, the lighting shows different expressions.

As we begin to question the society of mass production and consumption and move toward a mature society that is more conscious of the quality of life and work, we look at the situation in which craftsmen are subject to demands for lower prices compared to machine-made products and consider what we can do to protect the skills and lives of the successors of Japanese manufacturing, and of course to produce high-quality products at reasonable prices. The concept was based on what can be done to achieve this goal.

The challenge was to integrate 3D technology and digital manufacturing into the production process of handicrafts, taking advantage of the benefits of each.

The project also sought to examine the relationship between manual labor and the incorporation of the latest technologies and to explore how these technologies can help people develop their creativity in dramatic ways, rather than taking away their jobs, as has been observed with concern in recent times.

We proposed an attempt to merge traditional and new technologies as one of the new forms of manufacturing.

2019 A`Design Award Arts, Crafts and Ready-Made Design Award Silver Award Category, Milan/Italy